Solution for chiller/HP units with screw compressors

The CAREL solution for chillers/heat pumps with screw compressors has been developed around the pCO5+ range of programmable controllers. This application can manage both air/water and water/water units with screw compressors and continuous/stepped capacity control or inverter. The maximum configuration is one screw compressor in each circuit, with up to four circuits.

The main benefits offered by the CAREL solution are:

Compressor protection and reliability |

|

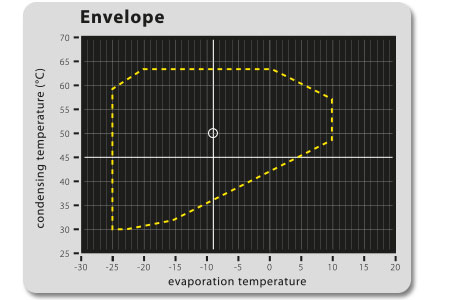

| Dynamic control of compressor envelope allows the effective compressor working point to be determined in real time. If this is close to one of the limits specified by the manufacturer, the software implements corrective actions to maintain and/or return compressor operation within the limits, thus guaranteeing compressor protection and reliability. The CAREL solution offers envelope management as standard for more than 40 models of the main compressors available on the air-conditioning market, such as Bitzer, Frascold, Hanbell and Fusheng. |

|

Unit efficiency and stable control |

|

|

pCO5+ is the true heart of the solution, reading the inputs and managing the outputs. The built-serial port means the controller can exchange data with the other unit actuators(EVD EVO, fan controllers, compressor inverter etc.), thus optimizing unit control and efficiency. Specifically, the use of EVD EVO driver and the electronic expansion valve (devices supplied as standard in the CAREL solution for screw CH/HP units), allow suction superheat control, guaranteeing energy efficiency through precise control in different outside and load conditions. |

|

Easy installation and maintenance |

|

|

sch Manager is the new commissioning tool that assists users in configuring and commissioning the software for chiller/HP units with screw compressors. sch Manager offers the following main functions:

|

|

Easy to customize |

|

|

The new standard software for chiller/HP units with screw compressor is not only a solution that is ready to configure and use, but is moreover a means that 1tool developers can use as a solid base for creating custom applications. The application program features a modular structure, making the code easy to understand and edit. Every function in the application is designed to be easily customized, thus allowing OEMs to implement their own custom algorithms.

|

|